The quality of gluten-free bread should be improved by focusing on starch first

The gluten-free bread market is growing, but the texture of bread is typically dry and the crumbs are non-cohesive and they stale rapidly. Researchers are working to improve the quality of the bread by studying its main component, namely the starch.

The gluten-free bread market is steadily growing mostly due to a deeper knowledge of celiac disease and gluten-sensitivity, as well as the popular association of the gluten-free diet with a healthy lifestyle.

However, gluten-free bread lacks the unique extensibility, elasticity and water- and gas-holding capacity that appear when the two protein fractions, glutenin and gliadin, are mixed with water and form the gluten network.

This means that gluten-free loaves of bread are typically dry, and stale rapidly, and they have non-cohesive crumbs.

Gluten-free bread, however, has one very important feature in common with other breads: its main component is starch - a type of carbohydrate with a complex molecular structure.

With a thorough understanding of starch, it is possible to make the most of it and to dramatically improve the quality of the gluten-free bread.

Postdoctoral researcher Laura Roman and Assistant Professor Mario M. Martinez from the Department of Food Science at Aarhus University are part of an international research team, who proposed a map, providing an overview of the existing knowledge of starch and how it relates to the process of making gluten-free bread:

- The science of starch is extremely complicated, and therefore the production of gluten-free bread is often based on trial and error, where the industry is experimenting with additives such as HPMC, xanthan gum, guar gum or psyllium as a water- and gas-holding agent. Currently, it is more of an art than a science. We are now trying to gather knowledge about the complex structuring role of starch at different scales - and its interplay with the gluten replacers - and to make this knowledge much more accessible to industry, Laura Roman says.

You may also want to read: Researcher wants to turn stale bread into packaging material

From starch to plate in one model

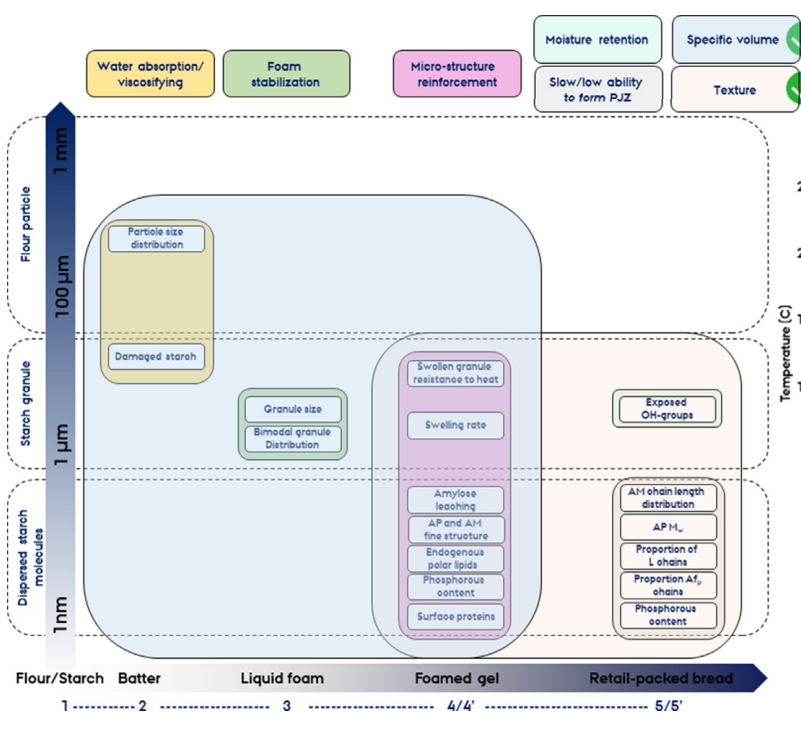

The new map (shown below) is based on findings from existing research, covering the entire process of producing and distributing gluten-free bread. It thereby contains everything that one needs to pay attention to regarding starch.

The x-axis represents the different processing stages from flour or starch to retail-packed bread, whereas the y-axis represents the different scales, which are relevant to the gluten-free structures -from molecules to flour particles.

The white rectangles define relevant physicochemical features to gluten-free bread quality mapped by processing and structural organization. The colored rectangles represent quality targets as affected by the mapped physicochemical properties that impact the most in the different processing stages.

- For example, in the second stage, when the ingredients are mixed and the batter, or dough is created, the water absorbing potential of the starch is crucial. The mixing step involves the distribution of flour particles or pure starch granules. In the case of flour, this is something that goes on at a macro level, as it involves particles of up to half a millimeter in size. In the case of granules, it goes on at a micro level, as the particle size is smaller. An excessive water absorbing capacity can result in limited development during fermentation and results in breads with a low volume, Laura Roman explains:

- The water absorbing capacity of flour particles and starch granules is highly influenced by whether the starch has been damaged during milling, as damaged starch have up to 5-10 higher water absorbing capacity. However, the negative effect of a finer particle size on dough consistency and bread quality can be corrected by increasing the water content in the receipt - and this is one of the many things that one must be aware of in the production process.

The new starch mapping for gluten-free bread. From the scientific article: Roman, L., Gomez, M., & Martinez, M. M. (2020). Mesoscale structuring of gluten-free bread with starch. Current Opinion in Food Science.

A crisp, moist bread and less food waste

The quality of the gluten-free bread greatly affects shelf life - and thereby the amount of food waste generated, and this is another good reason to optimize the decisions taking place during production, but also afterwards, in relation to packaging and storage.

- Although the mechanisms responsible for staling are not fully agreed, it is generally associated with as an increase in crumb hardness over time, and tends to be accompanied by a dramatic loss of quality. This can be explained by the fact that starch molecules tend to reassociate during storage, and during this process, moisture moves from the crumb to the crust. Mario M. Martinez states.

Finding the perfect moisture balance and low-staling starch molecules are the main challenges of gluten-free bread:

- On one hand, moisture absorption is a challenge to crispiness, but on the other hand, moisture loss causes bread staling. A major goal of packaging gluten-free bread is delaying bread from drying out, but also preventing it from excessive moisture absorption. However, we could potentially extend shelf-life without high-performing packaging by increasing our understanding of the behavior of the starch, Mario M. Martinez states.

| Additional information | |

Vi bestræber os på, at alle vores artikler lever op til Danske Universiteters principper for god forskningskommunikation. På den baggrund er artiklen suppleret med følgende oplysninger: | |

| Study type | Literature review |

| Funding | Aarhus University Research Foundation (AUFF Starting Grant), grant number 33764 |

| Collaboration partners | College of Agricultural Engineering, University of Valladolid, Spain Department of Food Science, Aarhus University |

| Read more | Download the scientific article: Roman, L., Gomez, M., & Martinez, M. M. (2020). Mesoscale structuring of gluten-free bread with starch. Current Opinion in Food Science |

| Contact | Laura Roman, Department of Food Science - Food Technology, lroman@food.au.dk, mobile: +4522317098 Mario M. Martinez, Department of Food Science - Food Technology, mm@food.au.dk, mobile: +4522406595 |